Imagine that you are walking down the road and you hear an crunch of metal. A car has just skidded and crashed into a building, and the engine is smoking. You quickly rush over and try to free the driver, but the seatbelt is jammed. Luckily you have a trusty pocket knife that has been with you for ages. You cut the seatbelt and drag the driver to safety, just minutes before a huge fireball engulfs the car.

All of that heroism cannot be done without a knife that is portable and yet so strong. A knife can also be used for a much simpler application. You receive a taped box, but you do not have scissors on you. You do have a handy knife, so you flick it open in style (swoosh!) and cut into the box to get your goodies.

Locking vs Non-Locking Folding Knives

A critical aspect of safe knife operation is the way each knife should be used and what safeguards are in place on the knife to protect you from injury. However, both types of knives will certainly help you cut open boxes, chop up an apple, or open an envelope.

The main difference between the two is that on locking knives, once opened, the blade is essentially “locked” into position. It requires a secondary action in the form of a button push, or some other manual action on the part of the user to close the blade.

A non-locking knife does not require a secondary action. A common example of non-locking blades can be seen on Swiss Army knives.

Locking Knives

Includes: Liner locks, frame locks, axis locks, lock backs, compression locks, button locks, collar locks, lever locks

Locking knives have the added benefit of having a knife locking system that keeps your knife blade securely open or closed. It allows you to keep the blade from unintentionally moving (and injuring you in the process) while you are cutting.

The downside is that when you need to lock open or close a locking knife, you need to activate a certain trigger mechanism (more about the different mechanisms below) in order to perform the locking operation safely. This can be difficult to do one-handed if you need to hold on to something while cutting it.

The next potential drawback is of a legal nature, as most countries outlaw the use of a locking knife in which its blade can spring open or be flicked open by a locking mechanism, such as a button, quickly. The knife can then potentially be used in a spontaneous stabbing or fight which can use serious injury.

Non-Locking Knives

Includes: Slip joints, friction folders

These knives form the majority of everyday carry (EDC) knives as they require a good, old-fashioned manual extension of the blade, preventing unwanted oopsies and mishaps.

However, you need to take extra care when utilizing these knives. Because of a lack of the locking mechanism, you need to make sure that you do not accidently put pressure on any part of the blade when cutting, as there is a fair chance that it will close on and nick your hand in the process. As such, these knifes have a projection from the base of the blade (called a tang) for the user to put weight on and prevent accidental closure.

History of Knife Locks

The earliest iterations of knives were of the non-locking variety. They were manufactured with a simple hinge that allowed the blade to pivot freely between the knife cover and extension.

When the Roman empire rose to power, they brought along better materials and designs that influenced the quality of knives. They made friction folding knives that made use of the tang (discussed earlier) and these knives were made from metals such as copper, iron and steel. Very durable indeed.

These knives were then refined by many cultures to fit the industries present in their time period. In fact, the Vikings made their own folding knives with carved bone handles and iron blades, and these became known as the peasant knives due to their use in the farming and agricultural domain.

Modern knives have improved on or retained similar designs, while replacing the materials used with steel, a durable and sturdy material.

Different Lock Types

We now turn to the various locking mechanisms that are prevalent in today’s foldable locking knives.

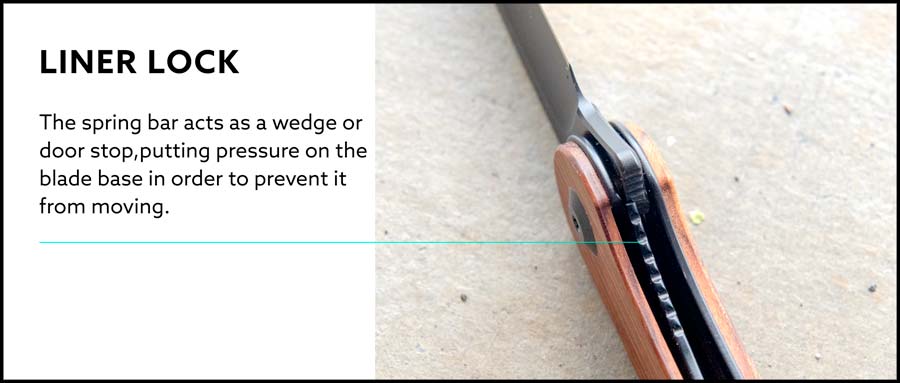

Liner Lock

A very common mechanism seen on folding knives. The lock mechanism works by having a side spring bar on the same side as the sharp edge of the blade, which lines the inside of the handle.

When the folding knife is closed, this spring bar is held under tension. When fully opened, the spring bar is slipped inward by the tension holding it in place to make contact with the base of the blade. Basically, the spring bar acts as a wedge or door stop, putting pressure on the blade base in order to prevent it from moving. Over rotation of the blade is prevented by a stop pin when the knife is fully extended.

If you want to stop the liner lock and close the blade, all you have to do is slide away the spring bar so that it vacates the spot it holds at the base of the blade. Continue sliding the blade shut.

Pros

- Cheap to buy

- Can close the knife with a one-hand grip without switching hands.

- Commonly seen on pocket knives

Cons

- Not as durable as frame locks

- You also place your thumb in the direct path of the blade when you go to release the spring bar.

Use in: Whittling when you are out camping or cutting packaging open.

Example: Spyderco Tenacious.

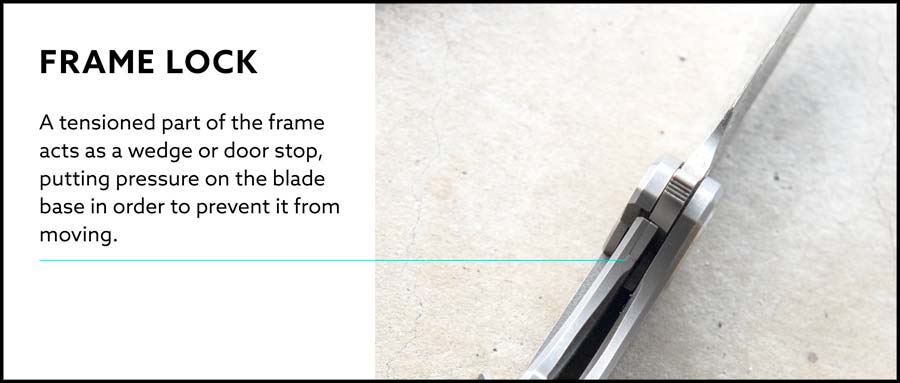

Frame Lock

I would liken the frame lock to be a liner lock version 2.0. While retaining many of the same principles from the liner lock, there is a fundamental difference. The spring bar, which slots into place at the base of the blade, is part of the knife’s handle and is often made of thicker metal. Closing a frame lock knife would be similar to the liner lock knife. These knives are typically made out of titanium.

Pros

- Easy to manufacture

- Can close the knife with a one-hand grip without switching hands.

Cons

Requires additional hardware, such as a lock bar stabilizer to make sure the frame does not interfere with the blade action.

Use in:

Example: Spyderco SpydieChef / Spyderco Dice.

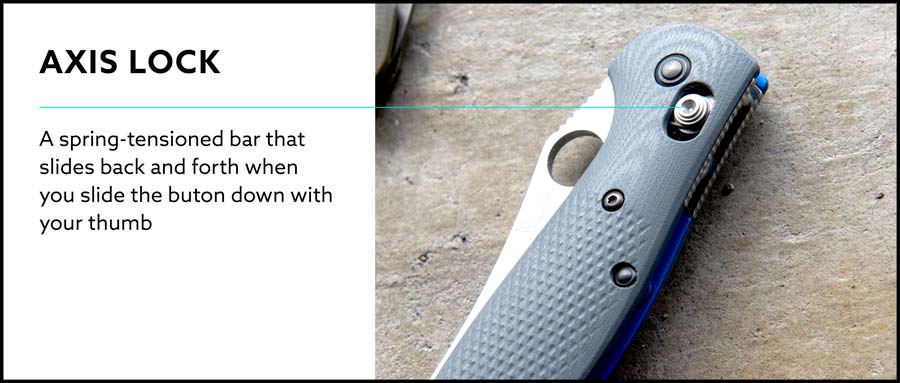

Axis Lock

A proprietary mechanism found in knives manufactured by Benchmade, the AXIS lock comprises of a spring-tensioned bar that slides back and forth when you do the respective action via two thumb grips on the knife handle. This bar connects to the base of the AXIS blade and locks into place when the blade is fully extended.

Pros

- Can close the knife with a one-hand grip without switching hands by drawing back the thumb grips and flicking the knife forward for the blade to drop.

- Ambidextrous usage.

- Fingers are not in the way of harm when closing the blade.

- Strong and tough mechanism

Cons

- Proprietary design only available on Benchmade knives.

- Complex to fix if they break

Example: Benchmade Mini-Griptilian.

Lock Back

This locking mechanism makes use of a notch on the back of the blade as well as on a pivoting arm. The notch on the arm correctly matches with the corresponding one on the blade in order to lock the blade open. The lock to release the blade is located at the back of the knife.

Pros

- Reliable strength and safety.

- Lock release is out of the way at the back of the knife, preventing accidental unlocking. Ensures your fingers are not in the way of the blade closing.

Cons

- Recommend that you use both hands to close a lock back knife.

- Inconvenient if you need to hold onto something and open/close the knife.

Example: Spyderco Chapparal Ti

Compression Lock

It can be thought of as an improved and inverted liner lock, as the liner is on the opposite side of where the blade folds into the knife cover (as opposed to a liner lock knife which has it on the same side that the blade closes into the knife cover). So the lock release is on the top of the knife’s handle. It also contains an elevated tab for you to easily disengage the liner lock to proceed with closing the blade.

Pros

- Locking mechanism does not expose your fingers to the path of the blade and keeps them out of harm’s way.

- One-handed usage.

Cons

- Prone to tension tuning in the frame of the blade.

- Inconvenient placement on the spine of the blade, sometimes awkward to use

Example: Spyderco Para 3

Button Lock

A very simple knife locking system – a button releases the blade and coiled spring tension fires the blade open. You would then have to manually extend the blade by flicking your wrist or using your fingers. A plunger (the round internal component of the button lock) engages a cut out in the tang of the blade, locking the open blade into place. With a button lock knife that is automatic, the button lock releases the blade and closes it as well in one swift motion.

Button locks are commonly seen on automatic knives.

Pros

- Strong locking strength

- Hand is out of the path of the blade

Cons

- Not ambidextrous.

- The legality of possessing button lock knives in your state/country/region might not be clear so check on the law before you buy. This requires additional work.

Example: Benchmade Osborne 9400

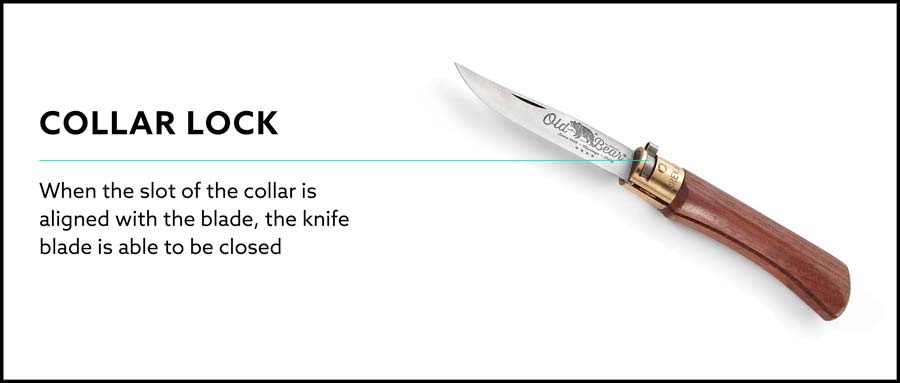

Collar/Ring Lock

A surprisingly effective and simple lock. This locking mechanism functions by having a ring with a slot placed in between the blade and the handle of the knife. When the slot of the collar is aligned with the blade, the knife’s blade is able to be closed. By extending the blade and twisting the collar to not align with it, the blade will not close on your hand at all and will remain locked open.

Pros

- Easy to operate

- Low cost

Cons

- Collar lock can get stiff due to wear and tear, preventing smooth and easy operation of the knife.

Example: Opinel

Lever Lock

In this locking mechanism, the tang of the blade has a notch to which a pin makes contact and keeps the blade in place. This pin is connected to a lever. Once the lever is lifted up from its resting position and pressed forward, it releases the pin that is holding the blade closed. A tensioned spring allows for the knife blade to swish open when the lever is pressed. The lever also functions as a lock when you return it to its original position after the blade is fully open.

Pros

- Mechanism holds the blade of the knife securely in place while it is locked.

- Found on Italian style knives and is visually pleasing.

Cons

- If lever or pin breaks, the entire locking mechanism is destroyed.

Example: Mikov 241 Predator

Types of Non-Locking Knives

These knives purely exist for satisfying the legal requirement that many states/counties/provinces and countries have regarding the possession of locking knives. But in some cases, people simply do not wish to carry a locking knife for fear of engaging the mechanism by mistake. So, what are the options available to you if you are not allowed to or do not wish to carry a locking knife?

Slip Joint Knives

At the outer side of the handle, there is a flat, tensioned back bar that acts like a spring. This bar comes into contact with the tang of a blade when it is fully extended. The back bar then exerts tension on the tang in order to keep the blade open. Be careful as any force on the spine of the blade (the top part) will cause it to close on your fingers. This type of locking mechanism is very common in Swiss Army Knives, such as the Victorinox Swiss Army EvoWood 17. However, they are not suitable for heavy-duty tasks due to a lack of a proper locking mechanism.

Friction Folders

These knives utilize friction to keep the blade in a closed position in between the knife scales (the material that provides you with grip and is located on either side of the knife handle). They also have an extended tang which you can use to open the blade. The tang lines up with the handle of the knife when the blade is fully opened. Thus, your palm keeps the knife securely open. They are definitely less complicated, but you ultimately forgo a locking mechanism that keeps the blade securely closed during pocket carry.

Conclusion

Phew! A whole lot of blades and locking mechanisms isn’t it? I hope you are able to decide on the perfect knife that is suitable for your needs! Thanks for stopping by and do contact us as always if you have any questions J

Zach Belmont has been working in the outdoor apparel industry in one form or another for over 20 years. During his career, he has worked at some of the most well-known adventure brands including Patagonia and The North Face in marketing, operations and product development. Zach currently lives in Wyoming with his wife and 2 kids.